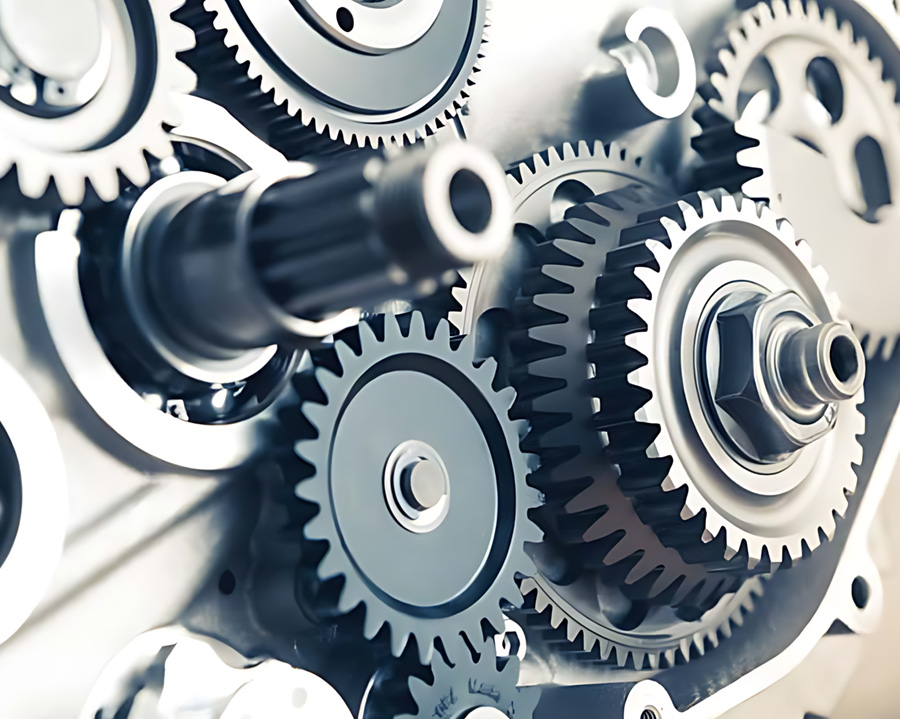

Gear units and transmission systems operate in almost every industrial process and are available in every possible shape and size, so they face a wide range of operating requirements and conditions. But regardless of the industry or application, all industrial drives face a common challenge: they must operate as reliably, efficiently and cost-effectively as possible. Industrial gearbox solutions meet these requirements and can help manufacturers and users find ways to optimize transmission performance and reliability. By using a systems approach, we can help you unlock the full potential of your gear units and improve performance and reliability in several ways:

large torque

Reduced size design

long lasting

Gain operational reliability

Improve energy efficiency

As a clean energy source that does not produce carbon dioxide that contributes to the greenhouse effect, wind power is rapidly spreading around the world. Large wind turbines (windmills) are giant machines. Many 2MW wind power equipment currently under co

More

The railway locomotive and vehicle axle system adopts different structural design due to different application conditions. The locomotive and passenger car have axle box, and the bearing is connected with the bogie through the axle box. The railway freigh

More

Textile machine bearings have stop rings on the outer diameter of the outer ring with sealing rings on both sides and are equipped with installed tapered bushings, lock washers and accessories. Textile machine bearings are mainly used to bear combined rad

More

Powder metallurgy bearings are made of metal powder and other anti-friction material powders that are pressed, sintered, shaped and immersed in oil. They have a porous structure. After being soaked in hot oil, the pores are filled with lubricating oil. Du

More