Textile machine bearings have stop rings on the outer diameter of the outer ring with sealing rings on both sides and are equipped with installed tapered bushings, lock washers and accessories. Textile machine bearings are mainly used to bear combined radial and axial loads, mainly radial loads. During installation and use, the dustproof effect is good and a certain degree of eccentricity adjustment can be achieved. Bearings for textile machines have stop rings on the outer diameter of the outer ring, sealing rings on both sides, and are equipped with installed tapered bushings, lock washers and accessories. It is mainly used to bear the combined radial and axial loads, which are mainly radial loads.

During installation and use, the dustproof effect is good and a certain degree of eccentricity adjustment can be achieved. Textile machine bearings are particularly suitable for supporting functions with limited radial installation dimensions. When selecting a bearing without an inner ring or a needle roller and cage assembly, the journal surface and housing hole surface matching the bearing are directly used as the inner and outer rolling surfaces of the bearing to ensure that the load capacity and operating performance are the same as those of bearings with rings.

Uses of textile machine bearings: Textile machine bearings are widely used in various mechanical equipment such as machine tools, metallurgical machinery, textile machinery, and printing machinery, and can make the mechanical system design very compact and smart.

Motor bearings, also known as motor bearings or motor bearings, are special bearings specially used on electric motors or motors. The bearing used in the motor is a part that supports the shaft. It can guide the rotation of the shaft and can also bear the

More

Berlin/Schleinfurt, September 23, 2010 For several years now, Schaeffler Industry has become a major partner in the development of rolling bearings for high-speed trains. When developing these bearings we work closely with vehicle manufacturers and operat

More

Wind power generation main bearing belongs to the field of wind power generators. The characteristics are: main bearing upper outer ring, main bearing lower outer ring, thrust cylindrical rollers, cage, main bearing inner ring. There are two rows of thrus

More

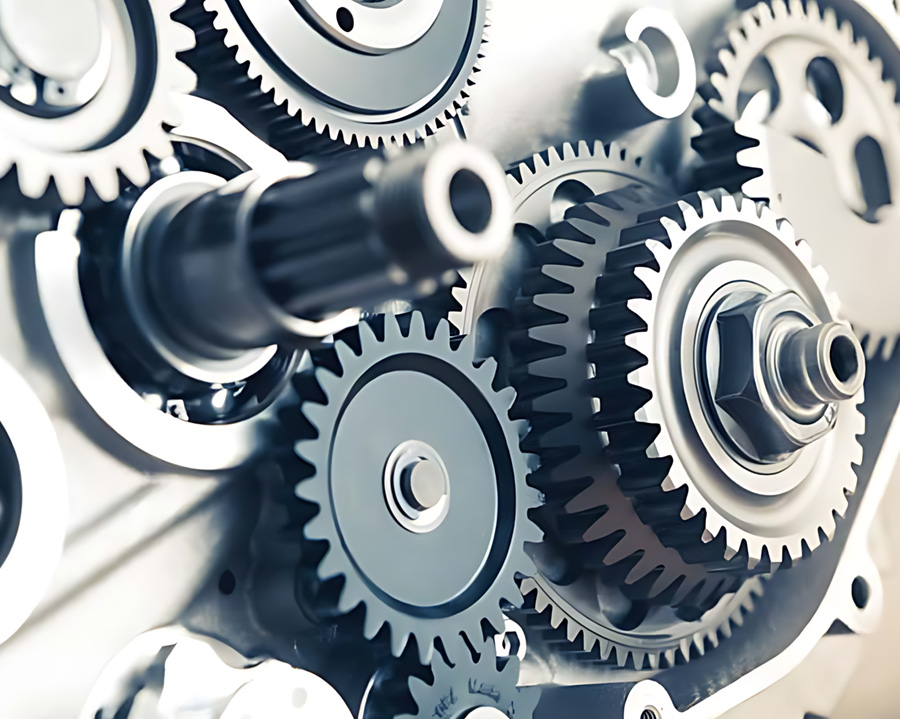

Gear units and transmission systems operate in almost every industrial process and are available in every possible shape and size, so they face a wide range of operating requirements and conditions. But regardless of the industry or application, all indus

More